The Manufacturing Institute Launches New FAME Chapter in Iowa

The Manufacturing Institute—the workforce development and education affiliate of the NAM—is launching a new chapter of the Federation for Advanced Manufacturing Education (FAME USA) in partnership with Grow Quad Cities and Eastern Iowa Community Colleges.

- FAME USA, which was founded by Toyota and is now led by the MI, is an employer-led solution that provides global-best workforce development through strong technical training, integration of manufacturing core competencies, intensive professional practices and intentional hands-on experience.

How it works: The new two-year apprenticeship-style training program at EICC—the product of two years of research by the MI and partners into local workforce needs—will allow students to earn while they learn to become highly skilled advanced maintenance technicians.

- Students spend two days a week in the classroom and three days a week with a sponsoring employer to get hands-on experience on the shop floor. At the end of their two years, they will have accrued over 2,000 hours of hands-on training and earned an associate degree in industrial maintenance.

- The new IA FAME – Riverbend chapter will be housed at EICC’s Blong Technology Center in partnership with Grow Quad Cities and seven local manufacturing companies: Amcor Global Rigid Packaging Solutions, LMT Defense, Novelis, Oertel Metal Works, PCT Ebeam and Integration, Smith Filter and SSAB.

- “Riverbend FAME expands what’s possible for students,” said EICC Chancellor Bryan Renfro. “It gives them a direct pathway to industry experience, job-ready training and long-term career success in manufacturing.”

Why it matters: Grow Quad Cities’ annual Top 100 High-Priority Jobs Report, released in August 2025, shows high local demand for industrial machinery mechanics, machinists and mobile heavy equipment mechanics—roles for which FAME graduates are perfectly suited.

- “We’ve been thoughtfully listening to what our local manufacturers need when it comes to future workforce,” said Grow Quad Cities Vice President, Business Retention & Expansion, Workforce Chris Caves. “And we know the need for maintenance talent in the region is growing due to an aging population of maintenance staff. FAME has been adopted positively by global manufacturing companies for the past 15 years, and we’re ready to demonstrate that the Quad Cities is serious about developing manufacturing professionals to satisfy this occupational need that will only grow in the years to come.”

- With support from the Arconic Foundation, the MI advanced its FAME efforts by partnering with Grow Quad Cities to convene local employers and launch the newest FAME chapter, strengthening workforce development for the Quad Cities’ robust manufacturing community.

Critical support: The new chapter was made possible thanks to grants from the Arconic Foundation.

- “The newly established FAME chapter serving the Quad Cities region will open new paths to great careers in manufacturing for local students,” said Arconic Foundation President and Treasurer Ryan Kish. “Arconic Foundation is proud to invest in this proven model to help prepare the next generation of manufacturing workers in the community.”

FAME spreads: IA FAME – Riverbend is the first FAME chapter in Iowa, expanding FAME USA’s footprint to 17 states, with 45 locations nationwide.

- As of 2025, six years after the MI took over responsibility for the initiative, FAME has brought together nearly 500 companies employing more than 1,200 students annually with 2,700 graduates and growing.

- FAME USA National Director Tony Davis said, “This chapter is really a great example of perseverance and engagement from local manufacturers, supported by great community groups and with a commitment to serve the needs of manufacturers by the college.”

What’s next: The first cohort of 10 students will start in fall 2026 and will graduate ready to join the manufacturing workforce full time in spring 2028.

Get involved: To learn more about FAME and starting a chapter, go here.

Photo of EICC Chancellor Bryan Renfro, credit EICC

The Manufacturing Institute Launches New IA FAME – Riverbend Chapter in the Quad Cities to Build Local Workforce

DAVENPORT, IOWA (January 27) – The Manufacturing Institute—the workforce development and education affiliate of the National Association of Manufacturers—announced today the creation of a new chapter of the Federation for Advanced Manufacturing Education (FAME USA) in partnership with Grow Quad Cities and Eastern Iowa Community Colleges.

FAME USA is an employer-led solution that provides global-best workforce development through strong technical training, integration of manufacturing core competencies, intensive professional practices and intentional hands-on experience to build the future of the modern manufacturing industry.

The new two-year apprenticeship-style training program at EICC allows students to earn while they learn to become highly skilled advanced maintenance technicians, putting them on track to start careers in an in-demand field while also building a talent pipeline to support the local manufacturing workforce. Students spend two days a week in the classroom and three days a week with a sponsoring employer to get hands-on experience on the shop floor. At the end of their two years, they will have accrued over 2,000 hours of hands-on training and earned an associate degree in industrial maintenance.

The new IA FAME – Riverbend chapter will be housed at EICC’s Blong Technology Center in partnership with Grow Quad Cities and seven local manufacturing companies: Amcor Global Rigid Packaging Solutions, LMT Defense, Novelis, Oertel Metal Works, PCT Ebeam and Integration, Smith Filter and SSAB.

The MI convened the partners for IA FAME – Riverbend for two years to conduct research into local workforce needs and to build community support for FAME. Grow Quad Cities’ annual Top 100 High Priority Jobs Report, released in August 2025, shows high local demand for industrial machinery mechanics, machinists and mobile heavy equipment mechanics—roles ideally suited for FAME graduates.

“We’ve been thoughtfully listening to what our local manufacturers need when it comes to future workforce,” said Grow Quad Cities Vice President, Business Retention & Expansion, Workforce Chris Caves. “And we know the need for maintenance talent in the region is growing due to an aging population of maintenance staff. FAME has been adopted positively by global manufacturing companies for the past 15 years, and we’re ready to demonstrate that the Quad Cities is serious about developing manufacturing professionals to satisfy this occupational need that will only grow in the years to come.”

With support from the Arconic Foundation, the MI advanced its FAME efforts by partnering with Grow Quad Cities to convene local employers and launch the newest FAME chapter, strengthening workforce development for the Quad Cities’ robust manufacturing community.

“The newly established FAME chapter serving the Quad Cities region will open new paths to great careers in manufacturing for local students,” said Arconic Foundation President and Treasurer Ryan Kish. “Arconic Foundation is proud to invest in this proven model to help prepare the next generation of manufacturing workers in the community.”

The manufacturers creating the FAME chapter will partner with EICC to support the FAME model locally.

“Riverbend FAME expands what’s possible for students,” said EICC Chancellor Bryan Renfro. “It gives them a direct pathway to industry experience, job-ready training and long-term career success in manufacturing.”

IA FAME – Riverbend is the first FAME chapter in Iowa, expanding FAME USA’s footprint to 17 states, with 45 locations nationwide. Originally started in 2010 by Toyota Motor North America to train the automaker’s maintenance technicians, the MI took over FAME operations to scale the program in 2019. As of 2025, FAME brings together nearly 500 companies employing more than 1,200 students annually with 2,700 graduates and growing.

FAME USA National Director Tony Davis added, “This chapter is really a great example of perseverance and engagement from local manufacturers, supported by great community groups and with a commitment to serve the needs of manufacturers by the college.”

The first cohort of 10 students will start in fall 2026 and will graduate ready to join the manufacturing workforce full time in spring 2028.

-FAME USA-

The Federation for Advanced Manufacturing Education provides global-best workforce development through strong technical training, integration of manufacturing core competencies, intensive professional practices and intentional hands-on experience to build the future of the modern manufacturing industry.

FAME was created by Toyota in 2010 and moved to the Manufacturing Institute for national scaling in 2019. Today, the MI continues to grow FAME USA across the country with the support of nearly 500 manufacturers.

-The MI-

The Manufacturing Institute works to build and strengthen the manufacturing workforce for individual opportunity, community prosperity and a competitive manufacturing industry for the future. This is done through implementing groundbreaking initiatives, convening industry leaders, conducting innovative research and promoting public policy that supports the sector as it meets the opportunity of modern manufacturing. As the 501(c)3 nonprofit workforce development and education affiliate of the National Association of Manufacturers, the MI is a trusted adviser to manufacturers, equipping them with solutions to address the toughest workforce issues. For more information on the MI, please visit www.themanufacturinginstitute.org.

733 10th St. NW, Suite 700 • Washington, DC 20001 • (202) 637-3000

Iowa Students Explore Manufacturing Through Innovators Quest

At Oskaloosa Middle School in Iowa, the future of manufacturing is taking shape today. The Quest for the Crystal of Innovation (also known as the Innovators Quest)—a gamified experience that introduces students to modern manufacturing careers—is engaging students in hands-on challenges in robotics, circuitry and teamwork.

At Oskaloosa Middle School in Iowa, the future of manufacturing is taking shape today. The Quest for the Crystal of Innovation (also known as the Innovators Quest)—a gamified experience that introduces students to modern manufacturing careers—is engaging students in hands-on challenges in robotics, circuitry and teamwork.

In an age where classrooms increasingly rely on digital learning, this active, physical experience helped some students uncover new strengths and interests—potentially leading to careers that will last a lifetime.

The quest: Developed by the Manufacturing Institute, the NAM’s workforce development and education affiliate, thanks to a grant from American Honda Motor Co., Inc., Innovators Quest is made up of four “realms” laid out in a board game format.

- These realms include hands-on building challenges that introduce students to core manufacturing skills, like problem-solving, teamwork and communication.

- As they seek to recover the “Crystal of Innovation,” students in grades 4 through 9 try their hands at 3D printing, robotics and other cutting-edge manufacturing concepts.

Manufacturers’ involvement: Manufacturers, associations, workforce partners and community engagement groups can sponsor Innovators Quest kits, which they can use at schools, summer camps, local community events, MFG Day events, company family days and more.

- By facilitating the experience, manufacturers serve as the connector between Innovators Quest and real-world manufacturing.

The reception: “It’s been fun to see the ones who really light up,” said Kristen McMains, talent outreach specialist at Musco Lighting, who brought the experience to Oskaloosa’s classroom. “Teachers have told us, ‘That student doesn’t usually engage like this,’ and suddenly, they’re the one leading their group.”

- “I learned that I’m pretty good with wires and building stuff,” said Kolter Ozinga, an 8th grader who participated in the experience. “I like electrical work and teamwork.”

The big picture: Innovators Quest comes at a critical time for the manufacturing workforce. A 2024 study by the MI and Deloitte projected that as many as 1.9 million manufacturing jobs could be left unfilled by 2033, when current 5th graders will be graduating high school. Today’s youth could be key to filling this talent gap—if they know the careers are out there.

- “Kids can’t be what they can’t see,” said MI President and Executive Director Carolyn Lee. “By sparking their interest in skills used in modern manufacturing, this student engagement activity illustrates the limitless possibilities of the many careers in our industry. The time to invest in our future workforce is now.”

Get involved: Interested in bringing Innovators Quest to your community? The MI is accepting orders for Innovators Quest kits through Jan. 31. Learn more about the kit and place your order today.

The Power of Holistic Workforce Development: Smurfit Westrock’s Story

Companies come to the Manufacturing Institute when they need solutions to their workforce challenges, whether that be a single area or the full spectrum of workforce needs. Smurfit Westrock, a global leader in paper-based packaging manufacturing, shows what is possible when companies partner with the MI to take a holistic approach to workforce development.

Heroes MAKE America: Smurfit Westrock’s partnership with the MI started with Heroes MAKE America (HMA), an initiative that builds connections between the military community and the manufacturing industry.

This partnership facilitated the hiring of veterans such as James Goppert, a retired United States Army Master Sergeant and now HR Business Partner at Smurfit Westrock. After more than 25 years in the Army, holding a variety of human resources positions both in the U.S. and abroad, James transitioned to civilian life with the support of the HMA program. HMA equipped him with insights into manufacturing as well as industry recognized certifications and connected him with Smurfit Westrock, an employer ready to see his potential.

With military training and experience, particularly with advanced technology, veterans are ideal candidates for manufacturing careers. Manufacturers that hire veterans gain dedicated, proven, dependable and skilled team members who bring a unique perspective and approach to problem-solving.

STEP Ahead: Beginning in 2020, Smurfit Westrock actively supported STEP ahead, the MI’s initiative to strengthen the modern manufacturing workforce. Through leadership development, mentorship and community building, STEP Ahead supports and empowers the workers leading the industry at every level—from the shop floor to the C-suite—helping individuals build successful careers in manufacturing while strengthening the industry’s future.

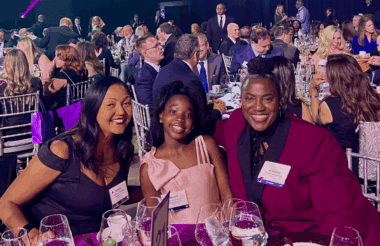

Smurfit Westrock’s own A’donna Garrett, Director of IT Digital and Portfolio Management, was recognized as a STEP Ahead awardee in 2025. As an awardee, she participated in a two-day leadership conference in Washington, D.C., ahead of the Awards Gala, focused on peer learning, leadership development and inspiration. During the Awards Gala, A’donna shared her success surrounded by cheering colleagues and her daughter, who saw firsthand what it looks like when hard work and leadership are recognized.

FAME USA: Smurfit Westrock is also a strong supporter of FAME, the Federation for Advanced Manufacturing Education), the premier American model of manufacturing skills training. As an employer partner across FAME’s national network, Smurfit Westrock sponsors FAME students to become highly skilled, professional maintenance technicians. The FAME model centers on employer leadership, allowing employer partners to play a role in everything from curriculum design to student recruitment at each chapter, building talent pipelines uniquely suited for their local needs.

Commitment to this investment is shared at the highest levels of the organization. On a visit to their facility in Athens, Alabama, Smurfit Westrock CEO Laurent Sellier met Steffen, a FAME graduate, and called him a great example of the talent driving Smurfit Westrock’s success.

The power of holistic investment: Smurfit Westrock demonstrates the power of investing in people and meet them where they are—whether they are transitioning from the military, starting their careers through FAME, or pursuing leadership opportunities, the impact extends far beyond a single location. It ripples through communities, strengthens industries, and builds the workforce of tomorrow.

This promise of workforce development done right is why the Manufacturing Institute exists; to help companies like Smurfit Westrock transform potential into opportunity and opportunity into lasting success.

MI’s Lee Talks AI, Workforce Training and More on “Workforce 4.0”

Artificial intelligence, the manufacturing labor shortage, training programs and more—all were covered in a recent episode of the “Workforce 4.0” podcast, featuring Manufacturing Institute President and Executive Director Carolyn Lee.

What’s going on: Among the first topics addressed by Lee last week when she chatted with podcast host Ann Wyatt for the episode “Manufacturing Hiring Trends: And What Employers Need To Know In 2026” was the still-persistent concern that AI will “take” jobs from human workers.

- “[W]hen you ask the average manufacturer, especially a large manufacturer, they would say they’ve been working with robotics and automation for many years now,” Lee told Wyatt. “This is not new. … Large language models and generative AI [are] new … but … manufacturers have [always] been at the forefront of technology evolution and innovation, and it has not eliminated all people. I see people wherever I go.”

- In fact, the more widespread automation and other AI applications have become, the more appealing some of the work has become. Lee told the story of a manufacturing worker nearing retirement age who told her, “I’ve been in this sector for 40 years. I’m 65. I want to stay longer because the job is safer. It’s interesting, I’m learning more in the last five years than I’ve learned my entire previous career, and I’m excited for what’s to come.”

- Manufacturers just need to train their workforces on the technology so their teams “are able to evolve” with it.

Humans in demand: Human workers are still very much in demand. In fact, the manufacturing industry still has a dearth of about 400,000 workers—a shortfall that, if current trends continue, will grow to 1.9 million by 2033, Lee said, citing data from a joint MI–Deloitte 2024 report.

- “When we do this updated paper, which will be in ’27, I think it will show a much bigger number because our retirements will have continued … [and] all this domestic investment is going to create new jobs,” she went on. That, coupled with the advancement of AI, will make workforce training—the kind the MI does—and worker upskilling even more important.

FAME-ously crucial: Lee and Wyatt discussed the Federation for Advanced Manufacturing Education (FAME), a national apprenticeship-style training program started in 2010 by Toyota and now run entirely by the MI.

- FAME now has “over 42 chapters in 17 states, training thousands of students in maintenance for an [Advanced Manufacturing Technician] degree,” according to Lee.

- “It is really an employer-led model where the employers are driving that commitment, driving the training, working in concert with community colleges and then local business entities to help support that network,” she said. “And then you’re growing the pool of talent and you’re building practices to solve this together so that we’re not fighting over a shrinking pool; we’re actually growing that pool.”

Heroes MAKE America: 2025 In Review

2025 was another successful year of building connections between manufacturing employers and the military community across the nation. The Manufacturing Institute’s Heroes MAKE America (HMA) initiative, which bridges the gap between manufacturers and skilled, job-ready transitioning service members and veterans, continued to evolve and expand to new heights. Read on to learn more about this year’s growth and standout achievements.

Continued success: HMA’s efforts to ensure manufacturers maintain reliable access to a military talent pipeline resulted in another year of growth.

- 6% increase in cohort enrollments.

- 92% graduate placement rate.

- Graduates earned average salaries of $77,524.

Since 2018, graduates have been placed with 500 companies across 49 states.

New pathways: HMA launched an accelerated Federal Aviation Administration Airframe and Powerplant (A&P) Certification training program, adding FAA-certified aviation mechanics to the HMA talent pipeline.

- The inaugural class was launched in April near McConnell Air Force Base in Wichita, Kansas, in partnership with WSU Tech and Textron Aviation.

- A second class launched in April near Fort Stewart and Hunter Army Airfield in Savannah, Georgia, in collaboration with Savannah Technical College (STC) and Gulfstream Aerospace.

- GE Aerospace Foundation supported the creation of the third A&P program near Fort Bragg, North Carolina, in partnership with Fayetteville Technical Community College (FTCC). This program will launch in 2026.

Additionally, HMA expanded training pathways at Fort Stewart in Georgia, launching a new Automation and Robotics course in partnership with STC.

Highlighting qualifications: The MI continues to lead the development and expansion of Manufacturing Readiness Badges which bridge the gap between military service and civilian manufacturing careers. These digital credentials translate military skills into a language that resonates with employers, making qualified talent easier to identify and streamlining veteran employment in manufacturing.

In 2025, HMA introduced two new Manufacturing Readiness Badges in Leadership and Logistics.

- Leadership Badges validate strengths in decision-making, communication, team coordination, and accountability.

- Logistics Badges acknowledge proficiency in inventory and warehouse management, supply chain operations, transportation, quality control, and data analysis.

- 9,183 Manufacturing Readiness Badges have been issued to date.

Real-time talent pipeline: The HMA Talent Network, powered by SmartResume, is a platform which enables employers to post jobs, search for qualified military candidates, create talent alerts, and proactively engage with job seekers in real time. Companies now have access to vetted candidates whose military skills are validated through Manufacturing Readiness Badges.

This shift modernizes the hiring process, shortens time-to-hire, and enables employers to build and manage a reliable military talent pipeline aligned with their ongoing workforce demands.

Connecting Employers with Key Talent: HMA hosted seven Military to Manufacturing Career Fairs, creating additional recruitment pathways for employers. By engaging talent both virtually and in-person on military installations, employers gained access to qualified, job-ready candidates across multiple regions, reducing recruiting costs and accelerating hiring timelines.

In the spotlight: HMA hosted an on-site Employer Spotlight at Fort Bragg, featuring Johnson & Johnson, the official healthcare supporter of HMA. The event highlighted career opportunities across J&J’s advanced manufacturing operations and provided attendees with guidance on J&J’s application and hiring process.

- Johnson & Johnson’s Chief Technical Operations and Risk Officer and NAM Board Chair and MI Board Member Kathy Wengel delivered remarks to an audience that included HMA alumni, future class participants, active-duty service members, veterans, and military spouses.

- She was joined by MI President and Executive Director Carolyn Lee and NAM President and CEO Jay Timmons, J&J Wilson Plant Manager and U.S. Army veteran Pete Goodridge, and North Carolina Department of Military and Veterans Affairs General Counsel Jimmie Bellamy.

This work matters: Nearly 200,000 service members transition out of the military each year, representing a highly skilled, job-ready talent pool. Veterans bring hands-on experience with advanced technology, safety-critical operations, maintenance, logistics, and team leadership, skills that directly align with modern manufacturing environments.

Read more about Heroes MAKE America and learn how you can get involved.

Delivering Results: FAME USA’s 2025 Year in Review

2025 was a landmark year for FAME USA—one defined by growth, innovation and a renewed commitment to delivering the global best model of manufacturing skills training.

FAME, the Federation for Advanced Manufacturing Education, is designed to develop highly skilled, professional talent to meet the unique needs and challenges of modern manufacturing. This employer-led program operates through more than 40 chapters across 17 states with nearly 500 companies using a FAME training program. Created by Toyota, FAME is now organized and supported by the FAME USA team at the Manufacturing Institute.

Read on to take a look back at this year’s successes!

Maintaining high standards: FAME USA launched Quality Assurance, a comprehensive review process that evaluates each chapter’s alignment with national standards. By holding every chapter to the same rigorous, industry-aligned standards, FAME USA ensures consistent high performance, strengthening the manufacturing talent pipeline nationwide.

- Following rollout in May, five chapters were reviewed in 2025

- Rocket City FAME in Huntsville, AL was the first chapter to be accredited and earned recognition as a Top Performing Chapter (Read more )

Nationwide expansion: The FAME network continued to grow, reaching new states and regions in response to growing demand nationwide.

The following five chapters began their journey with students in fall 2025:

- AL FAME – Built by Baldwin

- AL FAME – Huntsville Tech

- AL FAME – Magic City

- CA FAME – Central Valley (New state, first chapter west of the Rockies)

- IL FAME – Prairie Land

The following three chapters enrolled in FAME academy and will welcome students in 2026:

- KS FAME – Top City

- TX FAME – Navarro

- IA FAME – Riverbend (New state)

Continuing prosperity: Existing FAME chapters continued to connect students across the nation with careers in advanced manufacturing.

- 2,700 students graduated

- 1,300 students enrolled

- Dozens of new manufacturers joining the network

FAME on Capitol Hill: In November, the MI’s Chief Program Officer Gardner Carrick testified before the Senate Committee on Health Education, Labor and Pensions to recommend improvements to the Department of Labor’s Registered Apprenticeship program. In his opening remarks, he said that for manufacturing apprenticeships to be high-quality, rigorous, responsive and scalable, they must be employer-led like FAME. Read more about the hearing.

Connecting the network: The fourth annual FAME National Conference (FNC) convened in Charlotte, NC with the largest crowd to date.

- 250+ people attended

- Attendance has doubled in just four years!

We are deeply grateful to our new and returning sponsors whose partnership fuels the success of the FAME National Conference. Their support strengthens our ability to convene employers, educators, and workforce leaders from across the country to further the mission of building a highly skilled manufacturing talent pipeline.

For those exploring FAME, there simply is not a better event to attend! Special sessions will be offered at the Conference to help orient and arm stakeholders to create local chapters—be sure to register today!

Growing team of experts: We welcomed Tarina VanNatta as Associate Director on the MI’s FAME USA team. With nearly 20 years of experience in manufacturing and five years of experience in industrial automation education, Tarina brings expertise uniquely positioned to strengthen FAME’s impact nationwide.

This year’s growth and achievements were possible thanks to our partners; Coca-Cola Foundation, Smurfit Westrock, Autodesk Foundation, Aviv Foundation, Charles Shor Foundation, Charles Schwab Foundation, Arconic Foundation and ECMC Foundation.

Their investments strengthen FAME USA to further empower students, educators and manufacturers across the country to build a more resilient and dynamic workforce. We are deeply grateful for their partnership, leadership and belief in FAME’s mission, and we thank them for their continued support of the FAME USA network!

This work matters: FAME develops highly skilled, professional and sought-after talent to meet the unique needs and challenges of modern manufacturing. Every new chapter, graduate and employer partner strengthens a talent pipeline that fuels local economies, supports communities and keeps American manufacturing competitive. Investing in our people is essential to securing the future of our industry.

A Veteran Finds Her Next Mission at a Heroes MAKE America Manufacturing Career Fair

After decades of service in the U.S. Army, Nonya Stewart was ready for a new mission—one that would allow her to carry her commitment to service into civilian life. She found just that next chapter at Niagara Bottling, a leading beverage manufacturer proud to support veterans as they transition into new and meaningful careers in the industry. Her story demonstrates the impact of thoughtful partnerships like the one between the Manufacturing Institute’s Heroes MAKE America (HMA) initiative and Niagara Cares, the charitable division of Niagara Bottling, when we work collaboratively to support veterans.

The background: Originally from Albany, Georgia, Stewart joined the Army seeking structure, purpose and a new direction in life.

- What started as a leap of faith in her 20s turned into a 24-year career that took her across the world, including assignments in South Korea, Germany and Italy. During her service, she served as a logistician and rose through the ranks to Sergeant Major, the highest enlisted rank in the Army.

- “The Army taught me the true meaning of servant leadership and resilience,” said Stewart. “I learned that not everything will go as planned, but effective leaders adapt, stay composed, and guide their teams through challenges with purpose and flexibility.”

Coming full circle: When it came time to transition to a civilian career, manufacturing felt like a natural fit, familiar, hands-on, and aligned with her passion for logistics

- “I developed a passion for logistics work during my time in the military, where I learned that nothing operates smoothly without strong logistical support,” she said. “With 24 years of experience, I knew I had valuable skills to offer as I transitioned into the civilian world.”

A chance encounter: Stewart’s journey to Niagara Bottling began when she attended the HMA’s Military to Manufacturing Career Fair at Fort Hood in Texas.

- She only learned about the event the day before but attended with an open mind. Niagara Bottling stood out to her immediately after researching local manufacturers nearly a year earlier and remembered the company’s growth and advanced manufacturing systems.

- She introduced herself at the Niagara booth, shared her resume, and struck up an enthusiastic conversation with the team. Shortly after, she received an offer.

- Since 2023, Niagara Cares has proudly partnered with HMA to help create opportunities like this and to support transitioning service members nationwide.

A transition in action: Today, Stewart serves as a warehouse supervisor, leading a small team and ensuring accurate, safe movement of product. Her leadership style, which is rooted in calm and positive encouragement, is a continuation of her military training.

- “As a high-tempo company, we’re constantly moving and managing a team of three can certainly present its challenges,” said Stewart. “However, motivating my team and reinforcing the mindset that ‘we’ve got this’ are principles I carried over from my military career. Those experiences have shaped my leadership style and allow me to lead with positivity and confidence.”

A word of advice: Stewart encourages other service members to stay proactive when transitioning to civilian careers—and to seize opportunities like the HMA’s career fairs.

- “When I first started attending job fairs, I’ll be honest, I used to just stand there, feel intimidated and eventually walk out,” said Stewart. “But I realized I had to change my mindset. When you’re speaking with different companies, preparation is everything. Know your resume, be confident in your experience and make sure they can see your potential in that one conversation”

The MI says: “We are proud to support service members like Nonya as they transition from military service to successful civilian careers in manufacturing,” said MI President and Executive Director Carolyn Lee. “Through Heroes MAKE America’s training and career fairs, we connect employers with mission-driven talent who are valued for their skills and leadership.”

“Our partnership with the Manufacturing Institute and the Heroes MAKE America initiative reflects Niagara’s deep commitment to those who have served,” said Ann Chock, Head of Niagara Cares. “We’re grateful for the chance to support veterans as they transition into new careers and hope to play a small role in their continued success.”

Get involved: Heroes MAKE America is proud to partner with companies and organizations with Niagara Cares to support America’s military community and help fill critical manufacturing workforce needs. HMA connects skilled service members and veterans directly with employers who are committed to hiring and advancing those who have served. Together, we’re building a stronger manufacturing workforce for the future.

- Are you an employer looking to tap into the veteran talent pool? Learn more.

Siemens to Add 200,000 Electricians, Manufacturing Experts by 2030

Global technology company Siemens is expanding its electrician and manufacturing-expert workforces significantly (DC VELOCITY).

What’s going on: “In response to the nation’s urgent need for a skilled and adaptable workforce, Siemens today announced an expansion of its workforce development partnerships to help train 200,000 electricians and manufacturing experts by 2030.”

How they’ll do it: The firm will partner with community colleges, trade groups, technical programs and industry leaders to create training pathways, including certifications and technical programs.

- The move is a key piece of Siemens’ larger plan to contribute to “U.S. reindustrialization.”

Why it’s happening: Demand for skilled trades is exploding, according to Siemens, propelled largely by the rapidly expanding interest in and use of digital tools and artificial intelligence.

- “[E]lectrician jobs are expected to grow 9% from 2024 to 2034, well above the national average. According to the U.S. Bureau of Labor Statistics, an estimated 81,000 openings are expected each year, largely due to retirements and career transitions.”

- The article cites a 2024 joint study by Deloitte and the Manufacturing Institute, the NAM’s 501(c)3 workforce development and education affiliate, which found the manufacturing sector will need up to 3.8 million workers by 2033—and half of those jobs could go unfilled if current labor trends continue.

Now’s the time: “As the effort to reindustrialize our economy accelerates and a new industrial tech sector emerges, now is the time to build workforce development ecosystems with the scale and impact needed to prepare a new generation of AI-ready leaders in the skilled trades,” Siemens USA Interim President and CEO Ann Fairchild said in a release.

From the MI: “Manufacturers’ success will always rely on a skilled and capable workforce. Siemens’ commitment is a powerful example of the leadership and forward-thinking investment our sector needs,” said MI President and Executive Director Carolyn Lee. “Programs like this help build and sustain the workforce our economy depends on.”

Saint-Gobain North America’s Solution to the Workforce Challenge

Sustainable construction leader Saint-Gobain North America thinks it may have a solution to the nation’s dearth of manufacturing talent: “a long-term program that brings modern manufacturing into the classroom and the classroom to the site floor” (Newsweek).

What’s going on: In a recent op-ed, Saint-Gobain North America CEO Mark Rayfield discusses manufacturing’s status as a major economic engine—but says that to maintain that distinction, the sector “will need to fill 3.8 million manufacturing jobs over the next decade” (citing a joint study from Deloitte and the Manufacturing Institute, the NAM’s 501(c)3 workforce development and education affiliate).

- If current trends continue, 1.9 million roles could go unfilled, Rayfield continued, again citing the MI/Deloitte study.

Why it’s happening: “For years, students have been steered toward four-year degrees, while trade careers, especially in manufacturing, have been overlooked or stigmatized,” Rayfield writes.

- In fact, just 12% of American students have actually visited a manufacturing facility, according to the MI.

The fix: To fill those roles, Saint-Gobain North America recently launched the workforce development program “ Sustaining Futures, Raising Communities,” which “gives students a chance to explore immersive manufacturing environments with a focus on plant jobs that do not require an advanced degree,” according to the company.

- The company is already seeing some success from the program, Rayfield writes in Newsweek.

- “Across the country, we have already partnered with schools in North Carolina and Minnesota, and we will partner with over 10 additional high schools in Louisiana, Massachusetts, Texas, Pennsylvania, Missouri and Arkansas” this school year.

Why it’s working: “Let them get into our factories and see our employees and see that it’s not your 1950s manufacturing job, where you’re hammering the same nut as it goes by,” Rayfield told Semafor.

- Manufacturing jobs “are [artificial intelligence]-enabled, they’re tech-enabled, they’re Industry 4.0, they’re mechanical engineering jobs, and they’re extremely rewarding,” he added.

From the MI: “Programs like Saint-Gobain’s show what’s possible when manufacturers open their doors and help students see modern manufacturing up close,” said MI President and Executive Director Carolyn Lee. “These experiences don’t just change perceptions; they create pathways to meaningful careers and strengthen the workforce our industry needs to compete.”