Three Sisters Build Manufacturing Careers Together

For three sisters in Kentucky, manufacturing is a family affair.

Emily Bastin, Heather Craven and Hannah Geneve are all working in maintenance roles supporting various shops at Toyota Motor Manufacturing Kentucky. Growing up, they had disparate interests—while Emily had taken robotics classes in middle school and Heather had always enjoyed working with her hands, Hannah switched to manufacturing only after working in customer service. Today, all three of them are building careers in manufacturing together.

How they got here: Emily, Heather and Hannah found their way into manufacturing through FAME—an initiative for current and aspiring manufacturing workers that was founded by Toyota in 2010 and is operated today by the Manufacturing Institute, the NAM’s workforce development and education affiliate.

- The FAME Advanced Manufacturing Technician program offers on-the-job training and classroom education that combine technical training with professional practices and lean learnings to create world-class technicians. The two-year AMT program leads to an associate degree and the FAME certificate.

- “They came to my school—the AMT program—and I was like, you know, let’s give this a shot,” said Emily. “I didn’t realize I would have that kind of potential. This was cool stuff.”

The family business: Emily was the first of the three sisters to graduate from FAME, and she has been helping her sisters as they work their way through the program. Both Hannah and Heather are enrolled in FAME while working at Toyota, and they expect to graduate in May 2025.

- “We’re all working in the same plant, and if they need anything from me, I’m there to be supportive,” said Emily.

- “With schoolwork, I try to help Heather, and she tries to help me,” said Hannah. “We all help where we can.”

- “It’s nice to have that sister love to lean on,” said Heather. “They understand the frustration of school and work, and it’s been a pleasure to work with them.”

Opportunities abound: The sisters advise others who might not have considered manufacturing as a career—especially women—to give the industry a second look, emphasizing the sheer diversity of jobs on offer.

- “Working in manufacturing doesn’t necessarily mean you’re working on a factory floor,” said Hannah. “There’s an administrative side, an HR side—there’s a lot more to manufacturing than people expect.”

- “I do see us being examples for women who might not normally see themselves in the field,” said Heather. “You want to see women come in and say, hey, I did it, and you can, too. It’s nice to see yourself reflected back.”

The community: It’s not just their family ties that keep the sisters in manufacturing. All three sisters have high praise for their fellow students and colleagues, and for the supportive culture they’ve encountered at Toyota.

- “The mentorship I got helped me gain my confidence while I was learning,” said Emily. “And even now, the teamwork that goes into everything, every day—it’s been a nice surprise.”

- “Everyone has been super nice, super helpful and super welcoming,” said Hannah. “When you start out, it can seem intimidating, but everyone’s willing to help you out. They really want you to succeed.”

The last word: “It’s nice to feel like you’re a part of that network—that family,” said Heather.

The MI’s 35×30 campaign aims to increase the share of women in manufacturing to 35% by 2030 and spotlights outstanding women in the industry like these sisters. To learn more about Women MAKE America and explore its many opportunities, including its new mentorship program, go here.

The Federation for Advanced Manufacturing Education provides global-best workforce development through strong technical training, integration of manufacturing core competencies, intensive professional practices and intentional hands-on experience to build the future of the modern manufacturing industry. Learn more here.

How Mentorships Help Women Advance in Manufacturing

Jacqueline Cooley spends her days coaching manufacturing employees and helping them build better lives. So when she was looking to improve her professional skills and career trajectory, she knew it would be valuable to find her own coach or mentor.

Cooley found a great match through the Women MAKE Mentorship Program, a free initiative run by the Manufacturing Institute (the NAM’s workforce development and education affiliate), which aims to strengthen women’s careers in the industry by connecting them with peer advisers.

She recently told us about her experience with the program and what it has meant for her career so far.

A better life: Cooley is a better life coach at JBM Packaging, an “eco-friendly, flexible packaging” manufacturer in Lebanon, Ohio, which prioritizes hiring and supporting those who have been involved with the justice system. These “fair chance” hires make up about half the company’s approximately 160-person workforce.

- “I haven’t really found anybody else who does what we do,” said Cooley, whose job entails management of the fair chance program and its participants. “We have life coaching, financial coaching, our Wheels [car leasing] program. We do parental coaching; there are loans [employees] can take out. It’s holistic.”

A coach finds a coach: “I saw [the mentorship program] on the MI’s website and was immediately interested because I’d been looking for a mentor,” Cooley told us.

- “It has been really good. My mentor and I both work in human resources. She’s someone I can bounce ideas off.”

- “I’m at a point in my career where I wanted somebody else’s guidance, wanted to get [the benefit of] their experience in the HR world and learn the steps they took to get to the next level,” she added.

How it works: The MI pairs its mentors—all of whom are volunteers—with mentees based on personal and professional goals and interests, communication style and a dozen other criteria provided through a self-assessment.

- Cooley’s mentor—who works in human resources for another manufacturer—has already helped Cooley fulfill one of her primary goals: to broaden her network in the industry and meet more people.

- “My mentor has been in HR for 20 years or so, and she has a lot of contacts in the [Cincinnati] area and is well-connected,” said Cooley. “She’s invited me to her [workplace], had me talk to other people there, invited me to other [events]. I’ve met a lot of people through her.”

What’s next: Cooley, who said she is considering becoming a mentor herself once she finishes the nine-month program, said more women in manufacturing should participate.

- “It’s a great way to make connections with other women,” she said. “Don’t sell yourself short by thinking you don’t have anything to offer. The mentor can learn from the mentee as well as vice versa. It will open up opportunities for you.”

Dive deeper: To learn more about the MI’s free Women MAKE Mentorship Program, click here or contact the team at [email protected].

Manufacturers Should Think Local When Addressing the Workforce Crisis

No man is an island, and neither is any manufacturer. Indeed, local and regional ties have never been more important to the industry’s success, as companies seek to fill hundreds of thousands of open positions and secure a talent pipeline for the next decade.

That’s why building partnerships with local organizations, schools and leaders was a key topic at the Manufacturing Institute’s 2023 Workforce Summit in October.

- As MI President and Executive Director Carolyn Lee put it, “The current state of the economy calls for new ideas for solutions…. We’ll need to build more diverse talent pipelines and connect with our partners in the workforce ecosystem.”

The problem has changed: “The workforce challenges we are seeing are not transitory; they’re structural,” emphasized MI Vice President of Workforce Solutions Gardner Carrick. “Addressing these structural challenges are going to require local, regional solutions.”

- In this case, “regional” means approximately a 40-mile radius around a facility. Manufacturers should focus on sourcing the bulk of their workforce from this immediate area, said Carrick, since it is unlikely that workers outside of that radius would be willing to commute.

- Carrick noted that manufacturers will need other organizations to help their outreach. “We need to collaborate. This is not a problem that can be solved individually.”

Which partners? Manufacturers should seek out economic development boards, education partners and community-based organizations, as well as individual leaders within their local communities.

- “With every new partnership, identify the point person and the decision-makers,” Carrick advised. “Work with them to maximize the relationship. You want to build awareness and institutional memory of your company within that organization.”

- In addition, manufacturers can seek out regional chapters of the MI’s Heroes MAKE America, Women MAKE America and FAME USA initiatives—which help members of the military community, women and others find rewarding manufacturing careers.

Connecting industries: Manufacturers can also find partners within their industry sectors and create relationships with local schools.

- In another session at the summit, MI Director of Workforce Initiatives Pooja Tripathi pointed out that “A group of employers can sponsor a noncredit pathway—which is relatively inexpensive—at a community college, which can then use it to attract the workforce manufacturers are looking for.”

- Fresno Business Council CEO Genelle Taylor Kumpe added that manufacturers could work with high school counselors to challenge perceptions of manufacturing and the need for a four-year college degree. “We’ve seen internships and other short-term exposure programs work in attracting youth to the manufacturing industry,” she noted.

- Fresno Economic Development Corporation Vice President of Workforce Development Chris Zeitz gave general guidance on approaching industry partners: “Different manufacturers and organizations have different incentives and ropes to navigate. The speed at which different sectors like manufacturing, education and economic development boards make decisions and move can also vary.”

The final word: Caterpillar Foundation President Asha Varghese emphasized the importance of seeking local solutions for workforce challenges, a key element of the foundation’s efforts to strengthen communities nationwide. As she rightly noted, “A business cannot thrive unless the community is successful.”

A New Project Translates Military Experience for Manufacturing Employers

Manufacturers have long sourced great talent from the military community, helping transitioning and former military members apply their skills to America’s most pressing manufacturing challenges.

Through the Manufacturing Readiness Project, the Manufacturing Institute is now making it even easier for military veterans to find excellent civilian careers—and for manufacturers to build an outstanding and talented workforce.

The project: The Manufacturing Readiness Project aims to make military experience comprehensible to civilian employers via a digital credentialing system.

- Military servicemembers are awarded digital badges—stored in digital wallets—based on their military occupation and the training they received, giving both them and future employers a clear way to understand how their military experience prepared them for a career in manufacturing.

The details: The badges include a range of certifications in areas like general safety, general quality and general maintenance.

- Each badge includes a number of additional micro-badges signifying levels and types of achievement. General safety, for example, includes micro-badges in fields like workplace safety, environmental inspections and emergency response.

- These badges are also aligned with more than 300 military occupation codes across all five branches of the military, thereby translating military experience into terms that civilian employers will recognize.

What it means: For the MI, the workforce development and education affiliate of the NAM, this project represents a critical opportunity to expand the military-to-manufacturing pipeline.

- Currently, the MI’s Heroes MAKE America program trains transitioning military personnel in manufacturing skills and works to connect veterans to opportunities in manufacturing.

- The Manufacturing Readiness Project will enhance this effort by providing an avenue for veterans and transitioning personnel to highlight their military experience and enter the MI’s military-to-manufacturing pathway.

Why it matters: This initiative is one of the first of its kind to combine the use of the newest labor market technology tools—Learning & Employment Records, digital badges and digital wallets—to help workers find employment.

- This project is designed to be scalable across military occupations and civilian industries, thus opening the door to a broader range of servicemembers, veterans and employers.

What to expect: The pilot launched on Nov. 13—and within the first few weeks, more than 400 total badges have been awarded to transitioning and former servicemembers.

- So far, the initiative has received vital support from a range of organizations, including Solutions for Information Design, Jobs for the Future, Hire Heroes USA, the Manufacturing Skill Standards Council and Walmart. Following the pilot, the MI looks forward to seeking even more partners across the industry.

Learn more: For more information about the Manufacturing Readiness Project and the MI’s Heroes MAKE America program, please contact [email protected].

How Manufacturers Can Benefit from Military Talent

Looking for committed, disciplined employees to add to your workforce? In honor of Veterans Day, we’ll be highlighting how recruiting military talent—whether transitioning service members, veterans, National Guard members, reservists or military spouses—can help manufacturers address structural workforce shortages.

A productive match: At the Manufacturing Institute’s annual Workforce Summit in October, Maj. Gen. Kris A. Belanger, commanding general of the 99th Readiness Division, Army Reserve, spoke about the results manufacturers and military talent can achieve by working together.

- “The military offers diverse talent, very diverse. There are lots of ways that our training, roles and responsibilities overlap with those in manufacturing. Hiring military talent is a win–win situation,” she emphasized.

Making connections: During the “Leveraging Military Talent to Source an Essential Workforce” breakout session, MI National Director of Military and Veterans Initiatives Amy Thomas discussed how manufacturers can widen talent pipelines to include those affiliated with the military.

- “The Heroes MAKE American initiative trains and support military talent as they find a new career that utilizes their military training and experiences,” she said.

- “Since 2018, Heroes MAKE America has issued more than 6,000 industry-recognized certifications, achieved a 90% placement rate among graduates in more than 350 companies in 48 states and has shared information about manufacturing careers with more than 12 million individuals from the greater military community through social media, [Department of Veterans Affairs] newsletters and virtual and in-person industry events,” she continued.

Dive deeper: In addition to the Workforce Summit sessions, the MI held a Solution Series workshop in July to help manufacturers connect with military talent. The workshop offered manufacturers practical, actionable advice.

- For example, manufacturers should make sure the requirements listed in position descriptions are truly required for successful fulfillment of that role’s responsibilities, so that candidates coming from nontraditional backgrounds (such as military service) know they are welcome to apply.

- Companies should also make sure they know what military ranks and designations mean in terms of skills. They can go to the Civilian Leadership Equivalency Handout for guidance.

- For more tips, check out the MI’s Top 10 Solutions to Connect with Military-Affiliated Talent.

The last word: In conversation with Maj. Gen. Belanger, MI President and Executive Director Carolyn Lee noted, “With nearly 200,000 service members transitioning out of the military each year, the MI realized this was an opportunity to tap into that talent pool, teach them about manufacturing and bring them into our industry. That’s what makes our HMA program so exciting. We’re building those connections and providing those solutions.”

Get involved: Interested in learning more? Join the HMA team on Nov. 20 from 3:30 p.m. to 4:30 p.m. EST to learn how manufacturers can get involved in the program and benefit from this talent pool.

Thermo Fisher Scientific Opens Doors—and Career Paths—to Students on MFG Day

If you’re a jobseeker, Thermo Fisher Scientific wants you to know there are a plethora of job opportunities available at the company whether you have a science or engineering background or not.

At a well-attended MFG Day event for college students at its Frederick, Maryland, campus in October, both attendees and current employees said they were amazed to learn of the wide array of positions available at Thermo Fisher, a maker of life-sciences solutions and equipment.

Choose your own (career) adventure: “There’s a lot of opportunities here,” said Jude Ankrah, a cyber security engineer at the company’s Frederick location and one of the MFG Day’s event ambassadors, who helped lead student tours. “You can … make your own opportunities. There’s so much [internal] career movement. And it’s so flexible.”

- The MFG Day event drew about 60 students from four local colleges. It consisted of tours of the site’s distribution center, research-and-development cell biology building and corporate infrastructure and security center.

- Juan Argueta, who is working toward a cybersecurity degree at Frederick Community College, said he hadn’t expected the life-sciences giant to need people with his expertise.

- “I found out about it at school. I checked [the website], and there are actually a lot of openings in cybersecurity here,” Argueta told the NAM. “So I decided to come. There are so many great benefits [at Thermo Fisher]—including tuition reimbursement—for employees.”

Science not required: It’s a widely held misconception that people working at Thermo Fisher are all scientists and engineers, said Lisa Sweeney-Walker, senior executive assistant to Chief Scientific Officer Dr. Karen Nelson.

- “You don’t have to have a Ph.D. [or even] a science background” to get hired at Thermo Fisher, she said. “We have human resources, we have warehousing positions, we have other things.”

- In fact, the Frederick campus’s largest number of job openings is in manufacturing and distribution, said Frederick Site Leader and Senior Director of Manufacturing Operations Keith Howell, who spoke before the site tour. “We need both college-educated and non [degree-holding] hires,” he said.

Great strides: Thermo Fisher is doing some amazing things in science—and MFG Day attendees were able to watch some of its operations through interior windows at the R&D cell biology building.

- There, chemists are working to create “shells” for the next mRNA vaccines, Thermo Fisher Director of R&D David Kuninger told event attendees.

- Scientists at the company—who developed many of the tools involved in CAR T-cell therapy, a cell-based treatment technique in which a patient’s own T-cells are “programmed” in a lab to find and fight cancer cells—are now engineering an immune cell to fight cancer, he continued.

A path at Thermo Fisher: Regardless of your career interests, you’re likely to be able to pursue them at Thermo Fisher, said Shayne Boucher, a staff scientist in cell and gene therapy at the company.

- “Everyone has their own unique path,” he told the students. “There is an opportunity here to find out what works for you.”

Inside the MI’s Pathbreaking Workforce Summit

The best minds tackling manufacturers’ workforce challenges gathered in Atlanta last week to discuss hiring, retention, training and more. The Manufacturing Institute’s workforce summit convened almost 300 manufacturers, partners from education and training groups, philanthropy leaders and representatives from community-based organizations to share insights and brainstorm solutions.

The economic backdrop: Amid a persistently tight labor market, manufacturers are looking for immediate and long-term solutions to attraction and retention challenges.

- Chad Moutray, director of the MI’s Center for Manufacturing Research, provided the larger economic context for attendees, saying that “it’s not hard to be bullish about manufacturing. There continues to be signs of resilience in the sector despite a multitude of challenges.”

- “However, it exacerbates workforce issues, which remain the top concern of manufacturers, especially in a solid labor market,” he added.

Energizing connections: The MI was focused on helping participants learn from each other and form lasting and productive bonds.

- Organizations including the Georgia Association of Manufacturers, Siemens Foundation and River Parishes Community College sent leaders to facilitate conversations and share insights, while the generous support of WestRock, the Arconic Foundation and many others made the event possible.

- In breakout sessions, MI experts analyzed the key challenges facing manufacturers and shared proven workforce solutions like high school internships, female mentorship programs and regional sector partnerships.

Fresh insights: The two-day event was brimming with new ideas and fresh perspectives—too many to list in one article. Here is a brief sampling of the topics covered:

- People: The speakers highlighted manufacturers’ work to create positive company culture, prioritize flexibility and address issues like the shortage of child care. Maj. Gen. Kris Belanger also shared the importance of tapping into military talent pools like the U.S. Army Reserve. Programs like the MI’s Heroes MAKE America are making these important connections.

- Skills: To meet their needs for skilled workers, manufacturers are working with the MI, economic development boards and educational institutions to train the current and next generations of manufacturing employees. Workshop sessions showcased solutions from the MI’s FAME USA program, second chance hiring initiative and student engagement.

- Processes: Conversations in the popular “Brewing Solutions” rooms focused on ways manufacturers and workforce partners could tap into hidden populations, create attractive working environments and address policy barriers that restrict the adoption of innovative solutions.

Fearing you missed out? Don’t worry! There are plenty of ways you can plug into the cutting-edge work of the MI, the NAM’s workforce development and education affiliate.

- Get updates directly from the MI on the latest workforce insights and receive information about registering for the 2024 Workforce Summit.

- Join us as a sponsor for the 2024 Women MAKE Awards in Washington, D.C., on April 18 to support female manufacturing leaders and network with manufacturers and other workforce partners.

- Want more labor data and insights? Sign up for the MI’s comprehensive Workforce in Focus newsletter to stay up to date on the latest workforce trends.

The last word: “The MI’s unique positioning as both an insightful expert of emerging trends within the industry and an effective implementer of proven workforce solutions drives innovative problem-solving,” said MI President and Executive Director Carolyn Lee. “As we face structural workforce shortages, convenings like the MI’s Workforce Summit will continue to be crucial to build the types of partnerships and share important insights needed to ensure the readiness of the manufacturing workforce.”

Creators Wanted Tour Sets New Records at Ohio Finale

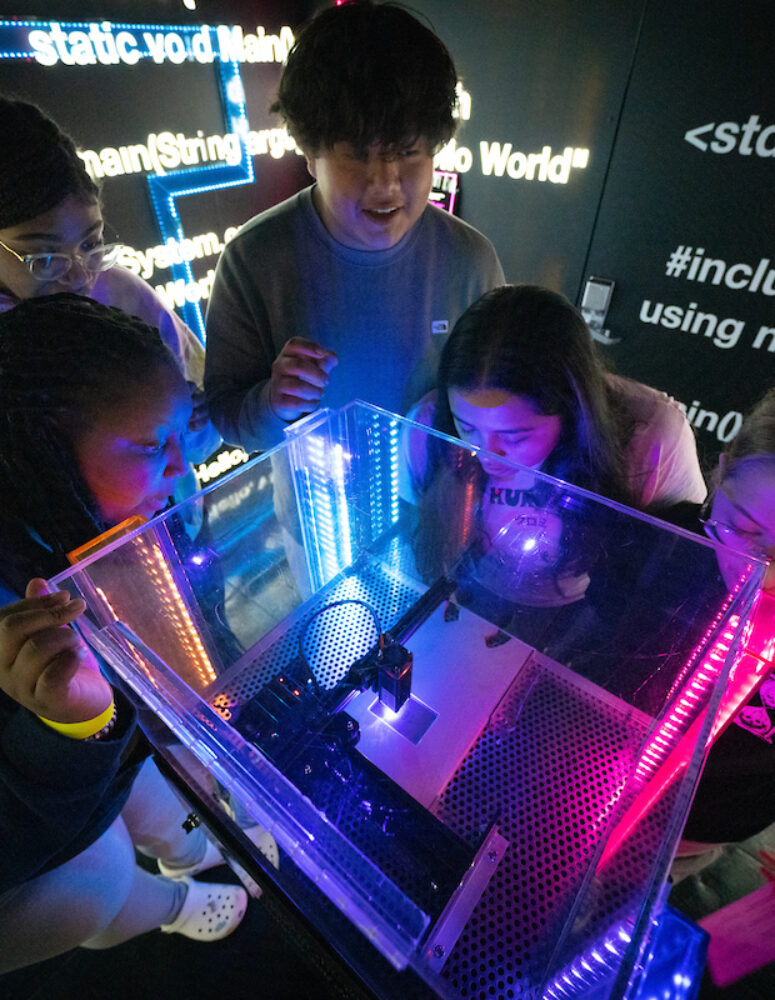

The size of the Great Pumpkin at the 116th annual Circleville Pumpkin Show—Ohio’s iconic fall fest—wasn’t the only record shattered there last week. The Creators Wanted Tour, a historic initiative of the NAM and the Manufacturing Institute to build excitement about modern manufacturing careers, reached new highs for engagement at its 20th and final stop.

Driving the news: The show attracted a crowd of more than 400,000, with “Creators Wanted” the most prominent brand seen and heard throughout the entire event. Of show attendees, the Creators Wanted activation pulled in a tour record of 2,024 participants comprising students and chaperones, taking the immersive experience’s overall total to just shy of 17,000 in two years.

- The digital campaign surrounding the stop collected an additional 110,000 email signups from students and career mentors interested in learning more about modern manufacturing careers, bumping the campaign’s email list above 1.6 million.

- The tour stop also saturated local news, with NBC4, 10TV CBS and WTTE Fox all sending live crews to the experience.

Why it matters: The stop, sponsored by the joint venture of Honda and LG Energy Solution and in partnership with the Ohio Manufacturers’ Association, comes at a critical time for the nation’s manufacturers, as they compete against other industries to fill available job openings today and win the interest of young people for the careers of tomorrow.

- For example, Honda and LG Energy Solution need to hire 2,200 workers within two years for their new electrical vehicle battery plant in Fayette County, Ohio.

- At the stop, Honda and LG Energy Solution joint venture associates were on hand to provide information about modern manufacturing careers generally and about opportunities at the EV plant specifically. The traffic around the experience was so robust that all recruiting materials were exhausted before the event wrapped up.

Zoom in: On Saturday night, the Creators Wanted team also reinforced the industry’s commitment to communities by leading the largest parade of the show, in front of tens of thousands who heard the public address system broadcast the industry’s call for creators and highlight the campaign’s career resources at CreatorsWanted.org.

- NAM President and CEO Jay Timmons, a proud son of Circleville and Chillicothe, Ohio, also addressed an assembling of Ohio’s young women leaders and their families, emphasizing their capacity to make a difference in manufacturing careers while at the same time noting mentorship resources available to them through the MI’s Women MAKE America initiative.

- The tour’s innovative approach received strong approval from state and local officials, strengthening the campaign’s ability to reach students and constituents. Ohio Treasurer Robert Sprague, State Auditor Keith Faber, State Sen. Michele Reynolds and State Reps. Brian Stewart and Mark Johnson, among others, stopped by to see what the buzz was all about.

Tour highlights: Beyond the pumpkin-centric celebrations, the tour also took its message of opportunity and rewarding careers to the new, state-of-the-art Logan Elm School, a combined elementary, middle and high school, as well as to students of the Ohio State University’s Center for Design and Manufacturing Excellence.

- At Logan Elm, Timmons was joined by OMA President Ryan Augsburger, Honda and LG Energy Solution joint venture representative and engineer Sandip Suvedi and representatives from Sofidel America. Honda engineer Meredith Reffey, who is now Honda America’s department lead for workforce partnership, joined Timmons and MI President and Executive Director Carolyn Lee at OSU. (The MI is the workforce development and education affiliate of the NAM.)

The big number: Post-tour surveys show that 84% of participants now view the manufacturing sector more positively.

On the record: “Closing our expansive 20-stop, 25,000+ mile tour at such a dynamic event serves as a potent reminder: the heartbeat of manufacturing lies within our communities,” said Timmons. “It’s in the eyes of the young dreamers in the crowd, the hands of our diligent staff and the spirits of every individual who championed our journey.”

- “The Creators Wanted Tour helped us shift perceptions, but we also know the hard work of continuing to improve perceptions and build the workforce of the future goes on,” said Lee. “The Manufacturing Institute, with our scaled-up efforts to drive solutions with manufacturers and across the industry and the robust digital network and resources the campaign has created will build on the tour’s momentum to do even more.”

The last word: “Our aspiration with Creators Wanted was straightforward yet audacious: to transcend traditional boundaries, step out of the corridors of Washington, D.C., and engage directly with communities across the country,” said NAM Managing Vice President of Brand Strategy Chrys Kefalas. “That’s exactly what we and the manufacturers who joined this tour and campaign did, and we’ve made a lasting positive difference in people’s lives that will outlive this tour and help the industry for decades to come.”

A Supply Chain Leader Supports Other Women in Manufacturing

When Carrie Shapiro began her career as an engineering student at the Georgia Institute of Technology, she didn’t expect to work in manufacturing—but the moment she walked into a manufacturing facility near her school for an interview, she was hooked.

“I’ve had so many opportunities in manufacturing that I never wanted to leave,” said Shapiro. “From the very beginning, I was able to keep learning and growing and making better relationships.”

Today, Shapiro serves as the vice president of sourcing execution at Georgia-Pacific—a pulp and paper company—where she guides procurement and uses her expertise in supply chain operations to benefit the company’s 110 facilities. As a leader in the industry, she’s also focused on helping potential creators understand all that manufacturing has to offer.

A changing world: Shapiro’s role has been especially important over the past few years, as the COVID-19 pandemic and its aftermath forced companies to adjust their supply chains and react to shortages in real time. For Shapiro, that process required rethinking risks, using data effectively and focusing on achieving stability before optimization.

- “The mistake that we often make is we try to optimize something that’s not stable,” said Shapiro. “If you’ve got chaos in your supply chain, you have no business trying to optimize it. You have to stabilize first.”

A need for humans: As Shapiro notes, data has become more readily available than ever before, and new tools are helping organizations make smart adjustments in real time. Yet, human decision-making and critical thinking still have a vital role at the center of manufacturing.

- “Tools are great, software is great, tech is great—but it should be an enabler and not a magic wand,” said Shapiro. “You still have to know your process, understand your current state and know your capabilities across the supply chain to make effective decisions. Tools don’t absolve you from doing the real work of continuous improvement.”

Leading by example: At a time when women are underrepresented in the manufacturing industry, Shapiro feels a responsibility to help other women succeed.

- She serves as a mentor with Pathbuilders, where she helps high-achieving women reach their fullest potential. She also coaches young engineers in the Steven A. Denning Technology & Management Program at Georgia Tech and serves as a longstanding member of the Next Generation Manufacturing Women’s Roundtable.

- “One of the most important roles that I play is to be a visible leader and to show there is a path to leadership inside manufacturing as a female,” said Shapiro. “Having someone who looks like you in a leadership position really matters. That representation matters, and it’s meaningful to people coming up in the organization.”

- On the strength of her long record of mentorship, Georgia-Pacific has nominated Shapiro for a 2024 Women MAKE America award, given by the Manufacturing Institute (the NAM’s workforce development and education affiliate) to outstanding women in the field. (Stay tuned for the ceremony!)

The last word: Shapiro encourages other manufacturing leaders to be active in lifting up individuals who might otherwise be overlooked.

- “I’ve had incredible supervisors who have pulled me up through the organization, who saw something in me that I didn’t see in myself,” said Shapiro. “Sometimes people look at a candidate and think they might be a stretch for the position—but they may just not look like a traditional candidate.”

New Manufacturing Institute Study: How Firms would Invest a Marginal Dollar with their Company

Washington, D.C. – The Manufacturing Institute, the workforce development and education affiliate of the National Association of Manufacturers, in partnership with Cognizant, released a study that examined the different approaches manufacturers take in making investment decisions.

“As manufacturers continue to evolve, the nature of work and skills must adapt to meet the needs of the changing industry. Manufacturing leaders must prioritize investments to best position their companies in a competitive marketplace and set themselves up for success over the long term,” said NAM Chief Economic and Director for the Center of Manufacturing Research Chad Moutray. “Three investment priorities emerged across manufacturer size and industry: increasing throughput and lowering costs where possible, creating new opportunities for growth, and building a stronger, more resilient workforce. Nearly all the companies we interviewed emphasized the importance of investing in their workforce.”

The study consisted of an online survey and in-depth interviews of manufacturing leaders from June to August 2023.

The following are highlights of the report:

- When asked about their top priorities for current dollars, nearly 74% of manufacturers reported building a robust and trained workforce as a key area for investment, which fits in with the larger macroeconomic conditions of the tight labor market and shortage of available workers.

- When business leaders were asked how they would spend a marginal $1 million, 61.5% would invest in new equipment. These findings point toward a desire to make smart investments that will transform operations and the production process, while also ensuring that the workforce can adapt to such changes.

- Additional areas of focus for marginal dollar investment included investing in improved processes and operations (60.2%), optimizing existing equipment (53.4%), investing in new equipment (51.7%), investing in new technologies (46.6%) and research and development (44.9%).

- When considering their future growth strategies, manufacturers identified a stronger domestic economy for growing sales (69.5%), increased efficiencies in the production process (67.8%) and maintaining a robust and trained workforce (67.0%) as the most significant factors in contributing to expansion.

Key Takeaway:

From survey data and interviews, three investment priorities emerged across manufacturer size and industry:

- Increasing throughput and lowering costs where possible

- Creating new opportunities for growth

- Building a stronger, more resilient workforce

-The MI-

The Manufacturing Institute builds a resilient manufacturing workforce prepared for the challenges and opportunities of the future. Through implementing groundbreaking programs, convening industry leaders and conducting innovative research, the MI furthers individual opportunity, community prosperity and a more competitive manufacturing industry. As the 501(c)3 nonprofit workforce development and education affiliate of the National Association of Manufacturers, the MI is a trusted adviser to manufacturers, equipping them with solutions to address the toughest workforce issues.

733 10th St. NW, Suite 700 • Washington, DC 20001 • (202) 637-3000